PCBX.com Resources

Your source for industry knowledge, news, and expert insights

Latest Posts

Article

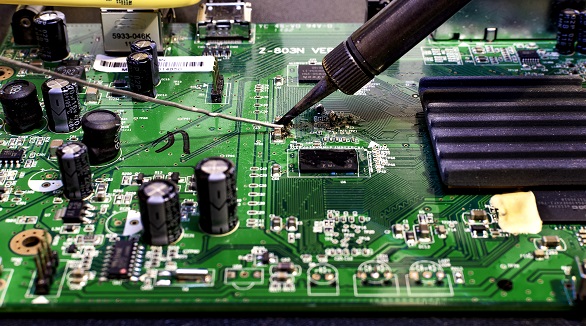

Selective soldering offers precision and efficiency for complex PCB assemblies, targeting specific areas with improved quality, cost-effectiveness, and flexibility, overcoming limitations of wave soldering.

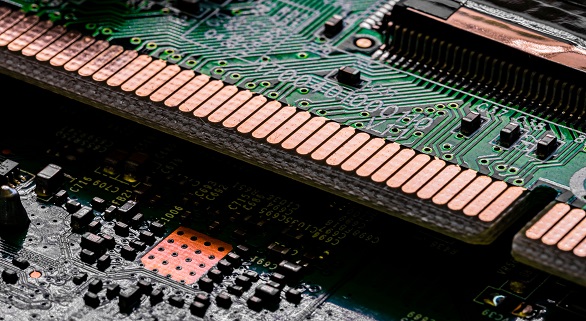

Precision in PCB stencil manufacturing is crucial for accurate solder paste deposition, reducing defects, and improving reliability. Key factors include material, technology, design, and maintenance.

SMD soldering mounts small components on the PCB surface for compact, automated designs but has high setup costs and repair challenges. DIP soldering uses through-hole components for robust, easily repairable, lower-volume applications.

Wave soldering quality hinges on several factors: consistent solder contact, precise heat management, optimal separation speed, and controlling solder surface tension. Key considerations include deoxidizing surfaces for effective wetting, strategic lead/pad design, and correct component orientation. Mastering these variables enhances PCB assembly reliability.

The article introduces the SMT (Surface Mount Technology) assembly process and future trends. Key steps include solder paste printing, chip mounting, reflow soldering, cleaning, inspection, and rework. Future trends highlight fast, flexible systems, green practices, and high-efficiency, intelligent systems. SMT's potential revolutionizes electronics manufacturing with wide industrial applications.