PCBX.com Resources

Your source for industry knowledge, news, and expert insights

Latest Posts

Article

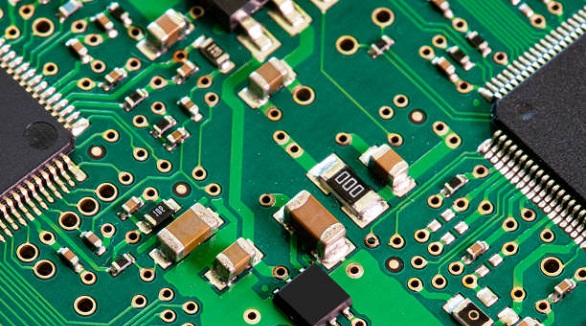

SMT revolutionizes electronics by enabling smaller, efficient, durable devices, with reduced costs and performance boosts, essential in various industries.

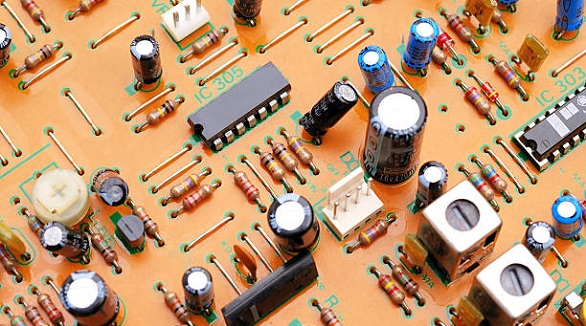

Populated circuit boards integrate electronic components for efficiency and reliability, utilizing SMT and THT for diverse applications across industries.

Through-hole assembly remains essential in electronics, offering strength and reliability, especially in critical applications, despite SMT's rise in compact designs.

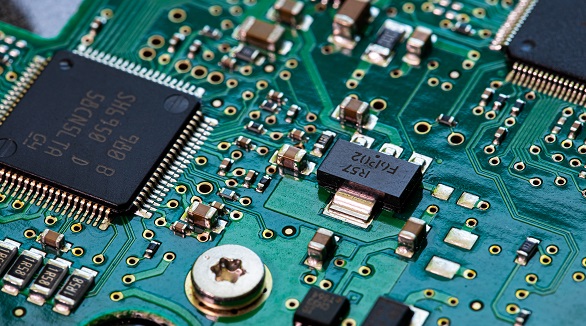

PCB pads connect components on circuit boards. Understanding through-hole, surface-mount, and BGA pads is key for effective PCB design and manufacturing.

SMT assembly streamlines electronics manufacturing with compact, reliable designs using precise equipment, meeting high-density demands and international standards.

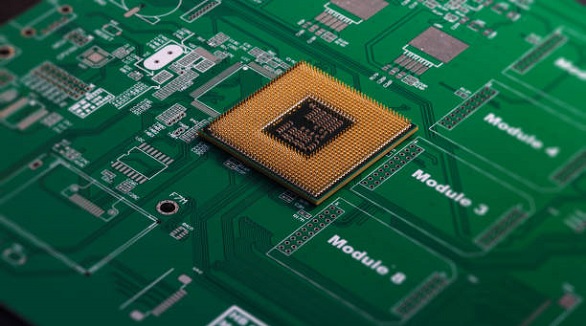

BGA assembly, challenging due to hidden joints and warpage, requires advanced techniques, skilled training, and strategic planning for reliable PCB production and minimized defects.

Through-hole technology remains vital in electronics for its reliability and durability. The article reviews its components, benefits, applications, and evolving trends like miniaturization, SMT integration, and automation.

Through-Hole Technology (THT) mounts electronic components by inserting their leads through pre-drilled PCB holes and soldering them. While durable and ideal for harsh conditions, THT is less space-efficient than SMT.