PCBX.com Resources

Your source for industry knowledge, news, and expert insights

Latest Posts

Article

Thermocouples in PCBs ensure accurate temperature monitoring; attach with solder, tapes, or epoxy based on application needs for effective thermal management.

Innovative tooling enhances PCBA tab removal by ensuring precision, reducing stress on components, and improving production efficiency and cost-effectiveness.

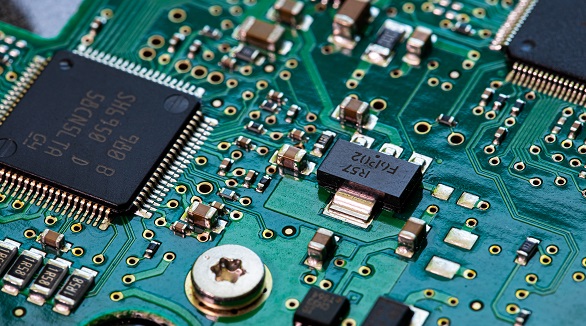

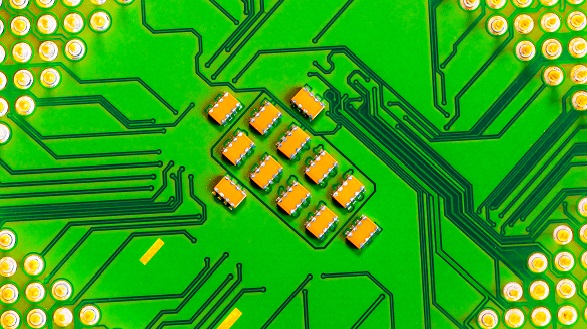

SMT assembly streamlines electronics manufacturing with compact, reliable designs using precise equipment, meeting high-density demands and international standards.

Efficient PCB assembly needs component standardization, design clarity, optimized workflow, material management, defect detection, automation, teamwork, lean practices, and IoT integration to meet quality and demand.

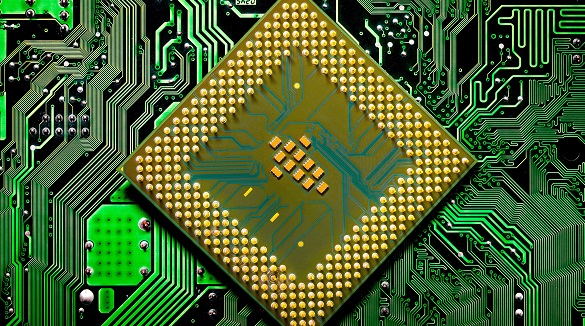

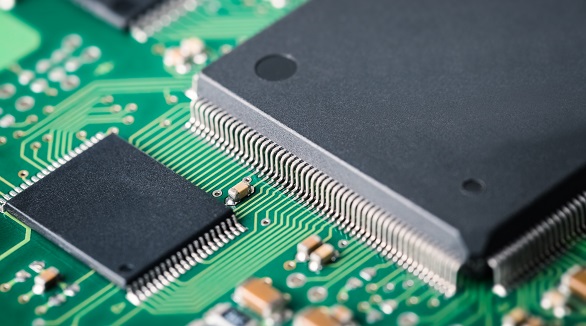

BGA assembly, challenging due to hidden joints and warpage, requires advanced techniques, skilled training, and strategic planning for reliable PCB production and minimized defects.

The article compares Ball Grid Array (BGA) and Land Grid Array (LGA) packaging technologies for mounting microprocessors on PCBs. It details their pros and cons, applications, and factors to consider for optimal design choices.

Surface Mount Technology (SMT) revolutionized electronics, facilitating smaller, faster, and more reliable products. It mounts components directly on PCBs, enabling miniaturization and automation. Though SMT boosts space efficiency, cost-effectiveness, and reliability, it poses rework challenges and requires high initial investment.

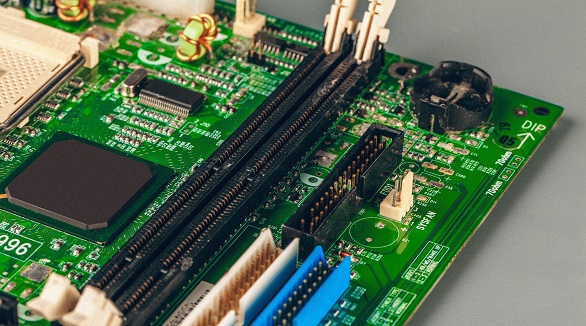

Through-hole assembly is a key PCB manufacturing technique offering reliability and mechanical strength. This article details design elements, requirements, and standards, including thermal pads, IPC performance levels, component types, solder joint quality, hole sizes, and annular ring dimensions, ensuring robust and manufacturable PCBs for various applications.