PCBX.com Resources

Your source for industry knowledge, news, and expert insights

Latest Posts

Article

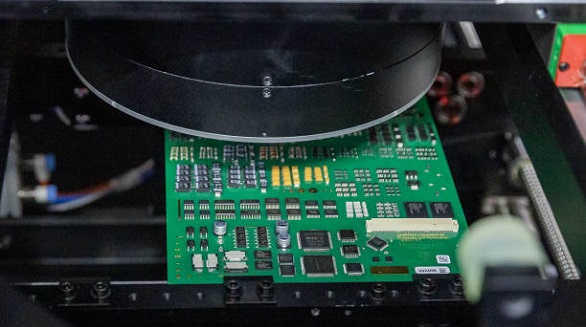

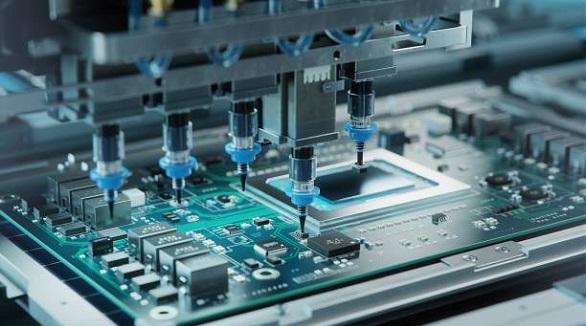

Pin in Paste (PiP) enables efficient, cost-effective PCB assembly, integrating through-hole and surface mount components in a single reflow pass, reducing costs.

Mastering hot air rework to remove SMD chips ensures precise control, protects the PCB, and is vital for effective electronics repair and upgrades.

ARM processors are efficient and flexible, ideal for many applications, while FPGAs offer custom parallel processing, crucial for specialized tasks requiring flexibility.

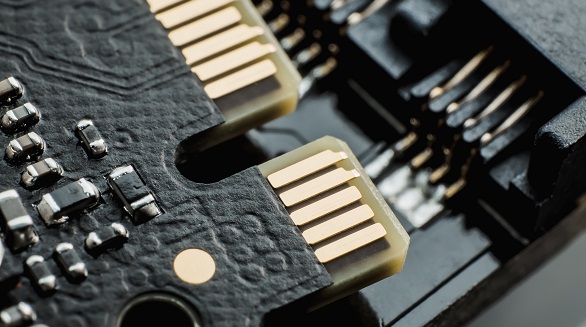

The 0603 SMD, vital for compact electronics, offers space efficiency, versatility, and cost-effectiveness, crucial for industries like consumer electronics and automotive systems.

Hex inverter ICs are vital in digital electronics for signal inversion, logic functions, oscillators, and data transmission, enabling efficient circuit designs.

Ensure SMT quality through detailed design, supplier rigor, and process controls, enhanced by testing and continuous improvement for reliable, defect-free products.

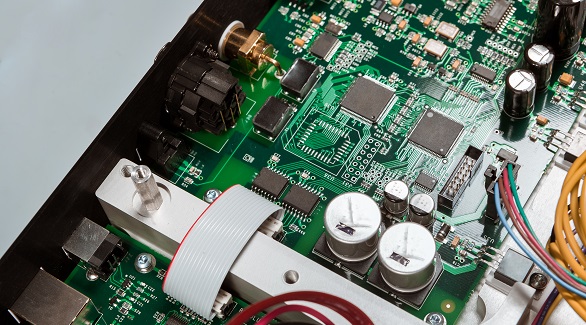

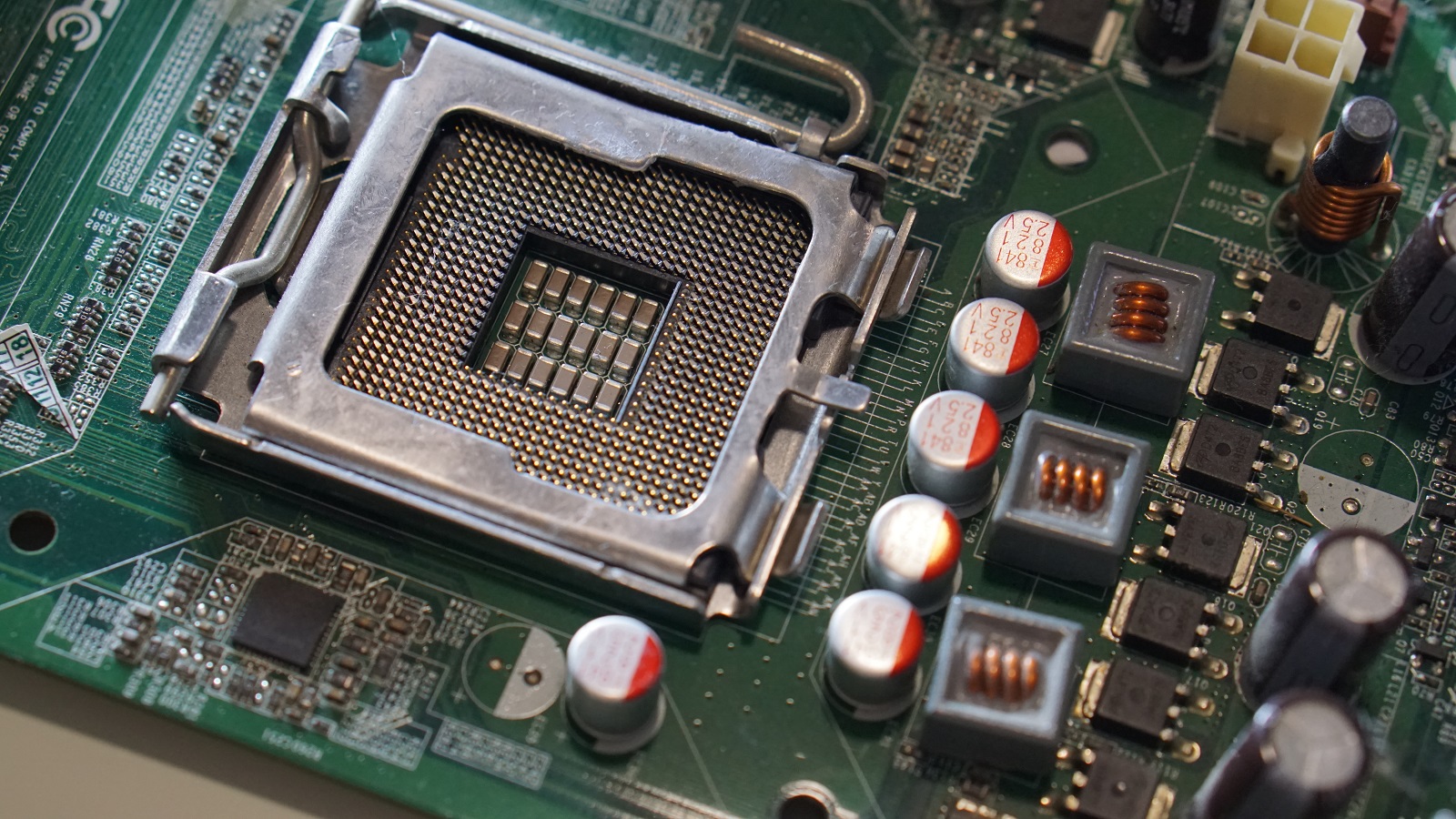

BGAs offer efficient, reliable IC connections with superior performance, comprising seven types ideal for high-performance electronics, optimizing space and thermal efficiency.

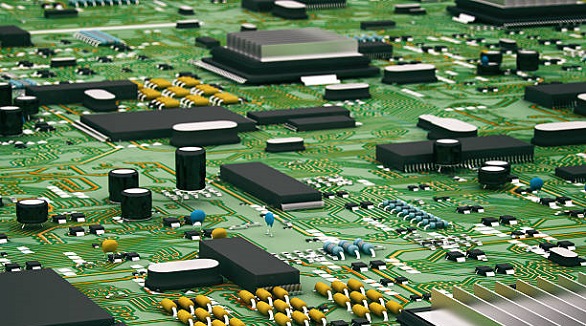

Selecting the right circuit components ensures functionality and reliability by matching specifications like voltage, current, and resistance for optimal performance.